New AZL Initiative Unites Industry to Benchmark Composite Rotor Sleeve Technologies Across Materials and Processes

New AZL Initiative Unites Industry to Benchmark Composite Rotor

Sleeve Technologies Across Materials and Processes

Wet filament, towpreg, and laser-assisted tape winding under real-world test conditions to identify optimal design and production routes.

Following the successful completion of its comprehensive market and technology study on composite rotor sleeves earlier this year, AZL Aachen GmbH is taking the next step with a new cross-industry collaboration: “Composite Rotor Sleeves – Experimental Testing & Benchmarking.” Building on insights generated with a consortium of 15 partner companies, this new Joint Partner Project (JPP) moves from theoretical comparison to applied experimental validation. Its aim is to benchmark composite rotor sleeve materials and manufacturing technologies under application-oriented test conditions—offering participants decision-ready data on performance and cost efficiency.

From Analysis to Application

Composite rotor sleeves play a key role in the performance and efficiency of high-speed electric drives for automotive, industrial, and aerospace applications. By replacing conventional designs without sleeves or metallic sleeves with carbon-fibre reinforced polymer (CFRP) sleeves, manufacturers can enable higher rotational speeds, optimized working windows, improved thermal management, reduced electromagnetic losses, and lower overall system weight. The optimal balance of material, design, and process parameters, however, depends strongly on the specific operating and temperature conditions—making experimental validation essential.

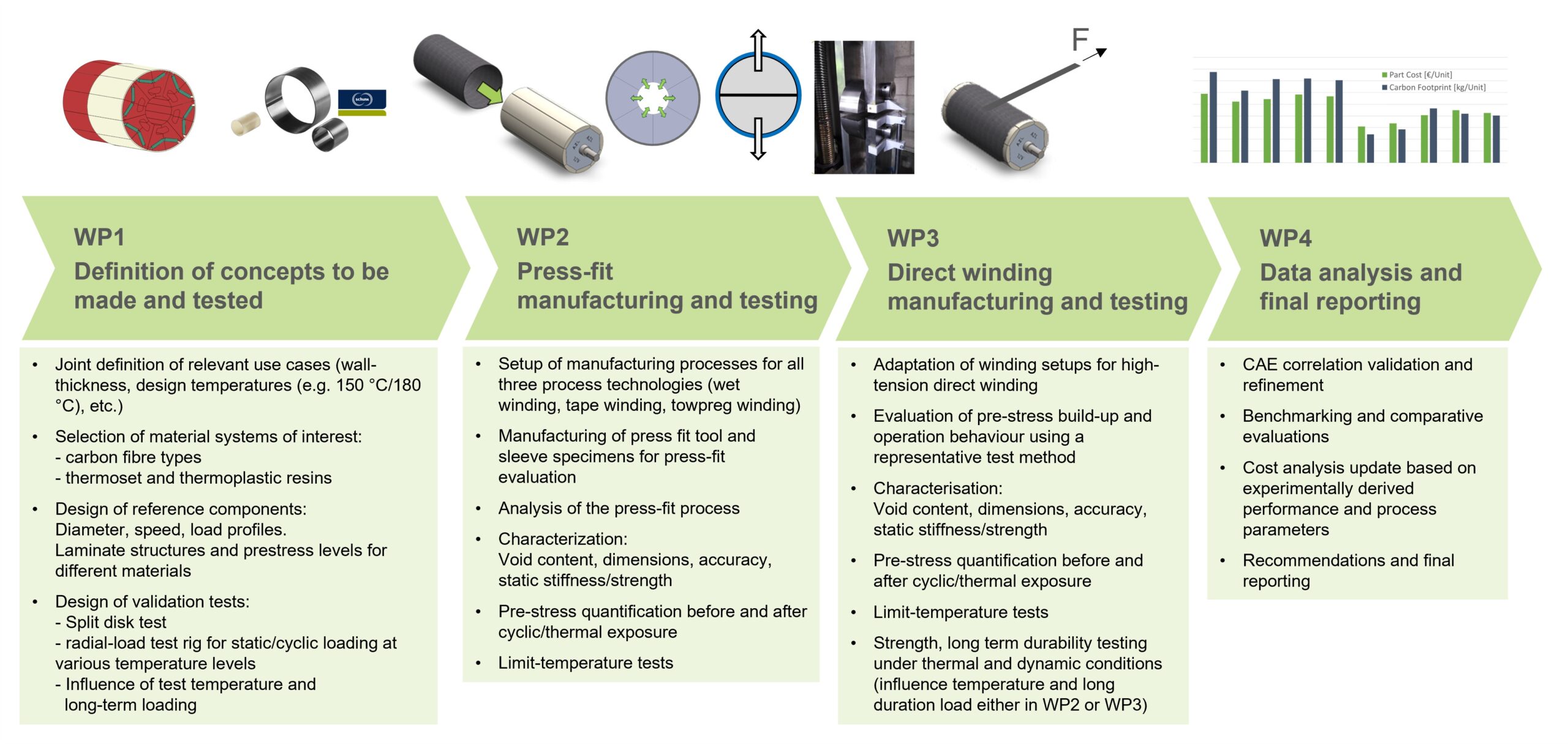

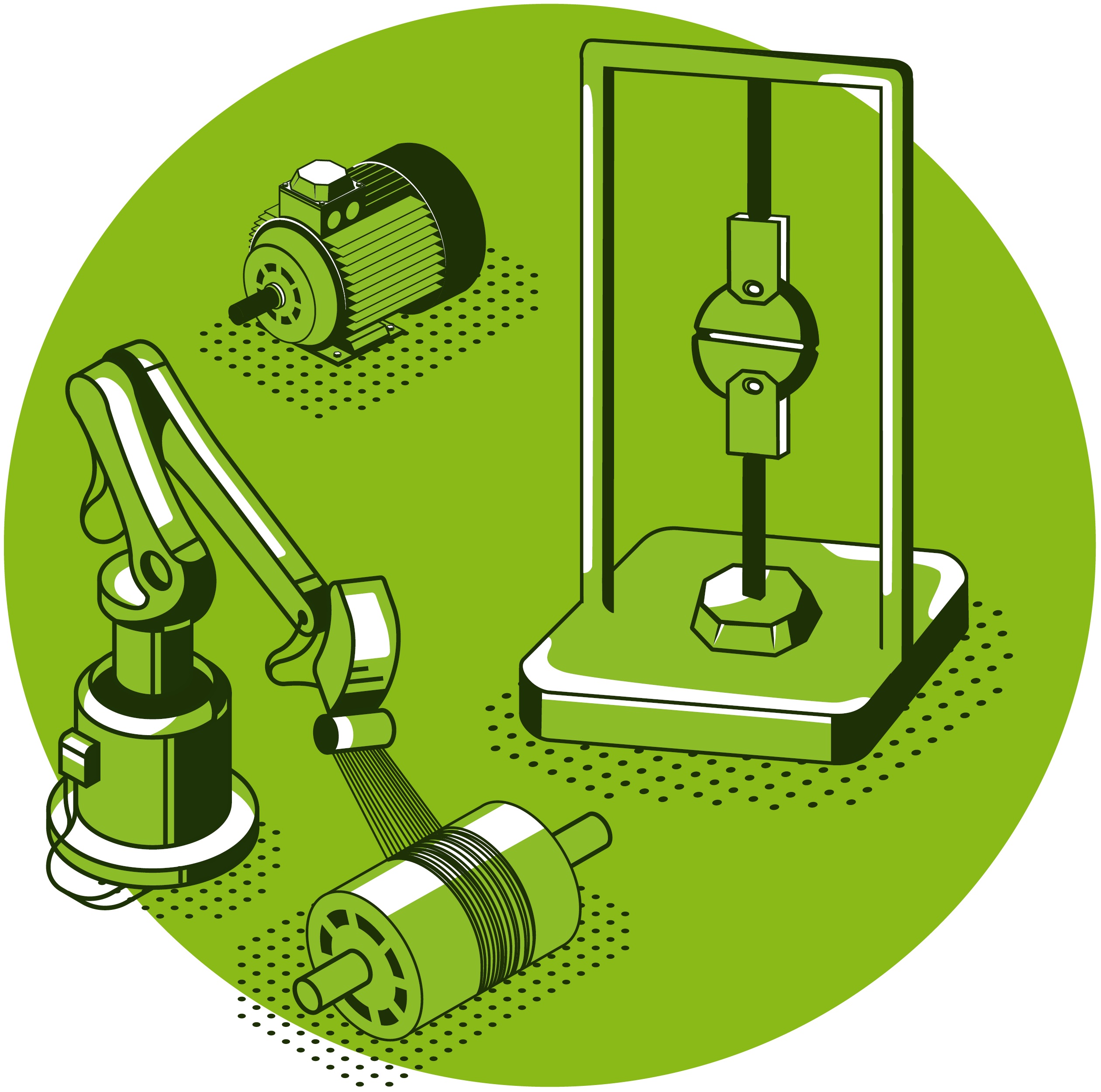

Within this new project, AZL’s engineering team will systematically investigate how different sleeve materials and manufacturing routes perform under realistic mechanical and thermal loads. The project will include wet filament winding, towpreg winding, and laser-assisted thermoplastic tape winding technologies, focusing on both press-fit and direct-wound rotor sleeve concepts. Comparative benchmarking will evaluate structural integrity, pre-stress behaviour, and temperature-dependent performance, while also quantifying production efficiency and cost-related KPIs.

Collaborative Infrastructure for Experimental Benchmarking

The initiative leverages AZL’s industry-leading infrastructure, combining design, manufacturing, and testing capabilities in one location on the RWTH Aachen Campus. Using specially developed testing setups—including a radial-load test rig and pre-stress analysis fixtures—the AZL team will replicate real-world operating conditions without the need for rotation. Static, cyclic, and creep tests at elevated temperatures will deliver deep insights into material and structural performance. Alongside the technical evaluation, the project includes a technological and economic assessment to identify the most efficient material and process combinations for industrial application.

Industry Perspective: Collaboration Across the Value Chain

The project’s collaborative setup enables companies from the entire composite and e-mobility value chain to jointly address key design and manufacturing challenges. Fabian Köster, Development Engineer Composites at Schunk Kohlenstofftechnik GmbH, highlights the importance of this cross-industry approach:

“As a technology leader and high-volume manufacturer in the field of rotor sleeves, Schunk considers it essential to actively shape innovation. Participation in the accomplished AZL project underlines our belief that future viability and competitiveness can only be secured through early involvement in technological developments. The AZL information event offers OEMs and partners across the entire value chain a valuable opportunity to exchange insights on the current state of rotor sleeve technologies, explore emerging trends, and jointly develop solutions for tomorrow’s challenges.”

Adding to this, Philipp Fröhlig, Head of Industrial Services at AZL Aachen GmbH, explains the broader value of the Joint Partner Project approach:

“Through our Joint Partner Projects, we translate peak-trend topics discussed within the various forums of the AZL Partnership into concrete, cross-industry collaboration. The new project on composite rotor sleeves is a perfect example: it connects advanced material development with real-world production and testing of high-speed electric motor components. By bringing together partners from across the composite value chain and utilizing the extensive know-how and infrastructure available within AZL and its ecosystem, we enable efficient, targeted innovation on all aspects of composite technologies, from design and process validation to mechanical testing and industrial implementation.”

Comments are closed, but trackbacks and pingbacks are open.